No matter if you’re an individual working on one of your projects or if you’re a business owner with hundreds of employees, money is, perhaps, the most precious sources we all strive to save. When talking about PCB production, you should never put a lower price over high-quality, however, you should know that there are other things that you could choose to do, all of which will save funds.

The price will depend on a wide range of circumstances, and those circumstances are exactly what you’ll have to consider when designing the layout of your product, especially since it’ll help you with lowering the expenses you’ll have in the end. Hence, without further ado, let’s take a closer look at the 8 smart ways you could save cash when manufacturing PCBs:

1. The Measurement of The Panel Should Be at a Minimum

Although this is something that’ll be quite logical for a lot of people, it’s still worth mentioning, especially since it’ll have a huge influence on your budget. The larger the scope is, the more it’ll cost you, hence, you’ll need to attempt to maintain the dimensions to a minimum.

Now, you should remember, this also goes the opposite way around, which indicates that if you choose to make it smaller than usual, the fabrication company will need to utilize specific tools and equipment to put it together, so, it’ll also be more expensive. All of this implies that you’ll need to discover the perfect balance between the size and complexity of putting it together.

2. Never Opt For Low-Quality Materials

If there is one single thing that you should take away from this article, it’s the fact that you should never opt for low-quality materials. So, before you order the production plant to utilize those alternatives, low-cost materials, think about how long it’ll be able to operate. Will it fail after a few days or weeks?

What does this mean? Basically, if you choose cheaper supplies, you’ll most likely end up losing a lot of funds later on, mostly because almost all of the boards will probably fail. Hence, when you’re choosing the materials, don’t forget to utilize the ones that standard and high in quality.

3. Don’t Choose Unconventional Shapes

You should always strive to create a printed circuit board in conventional, rectangle, or square shape. Of course, if you have some weird looking container where you’ll need to fit it in, you’ll need to opt for the shape that’ll suit your demands, but, if you don’t, avoid it at all costs. Why?

Well, if you pick a shape that is unconventional, it’ll definitely make your production expenses higher than usual, which is something you’ll definitely want to avoid. Keep in mind, you’ll want to ensure that you know all the board types offered by a particular PCB fabrication company, and if you don’t you could visit this website for additional information on the types you can get.

4. Larger Hole Diameters Are Budget-Friendly

Similar to how the size of your PCBs can influence the price, the holes can as well. This means that the smaller the rings and holes are, the more tools the plant will have to utilize, which will cause your expenses to rise. In most cases, the production plant will charge you more if you need the holes to be tinier than 0.4 millimeters, hence, ensure that you avoid this.

5. Using Standard Parts And Measurements is a Must

You might not realize this, but there is a pretty good reason why the entire electronic industry utilizes standard measurements and parts – it makes every single process easier for everyone involved. In order for you to dodge spending your funds on having the manufacturer put together your unconventional board by hand, you should stick with the standards in the industry.

6. Always Choose to Mount The Parts on The Surface

Unless you trying to build something truly daunting and complicated, it’s better if you choose to mount all of the parts to the surface of the board, something that is commonly referred to as exterior mount devices. Why should you do this? Well, there are some pretty good reasons.

For starters, by utilizing surface mount parts, you’ll be capable of lowering the number of holes the manufacturer needs to drill, which implies that you’ll lower your expenses. Second, this will also lower the number of tasks required to solder each part onto the board, and lastly, you’ll be capable of obtaining the PCBs quicker.

On the other hand, if you do end up choosing mixed-part tech, that will, in most cases, incorporate both thorough-holes and surface-mount parts, you should be prepared to spend more than you initially planned or would. This is why you may want to avoid this and stick with installing the parts to the surface.

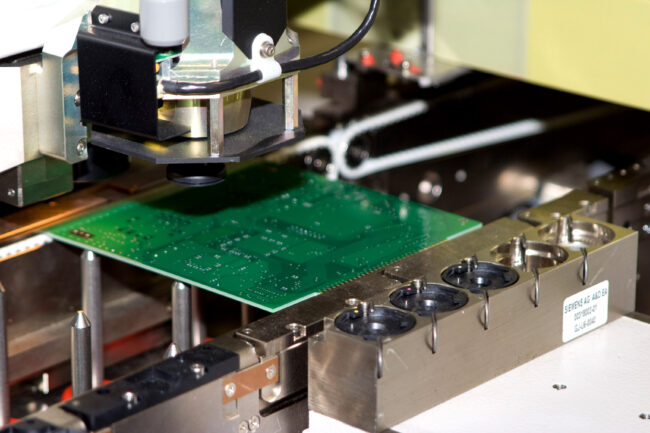

7. Ensure That The Boards Are Ready For The Panels

At the fabrication plant, the PCBs are molded into one huge panel with a lot of other printed circuit boards, or just yours – which will depend on the shipment you ordered. At this stage, you’ll be able to conserve a lot of cash if you utilize the largest panel scope available at the production plant. Is this really necessary? Yes, it is, especially since placing all of the boards on 1 panel indicates that a pick & place device could get all of the components set in one go, without needing additional time or equipment for setting it up.

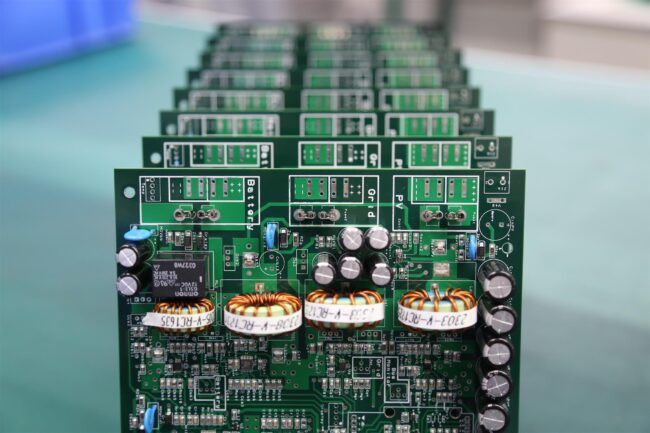

8. Say “Goodbye” to The Additional Layers

Last on the list, but not least important is that you should carefully think about whether or not you require excess layers. After all, the contrast between a 2- and a 4-layer PCB is double. So, you should definitely try and keep things snug and neat during your next design, and always utilize only the number of layers you actually need.

Conclusion

As you were capable of reading and learning, there is a wide range of things that you can use to conserve your funds when manufacturing printed circuit boards. And, if you choose to follow all of the tips mentioned above, you won’t only ensure that you conserve your capital, but you’ll ensure that you obtain high-quality PCBs.

So, now that you’re aware of all the cost-efficient things you can and definitely should do, you might not want to waste any more of your time. Instead, while keeping all the aforementioned tips in mind, start looking for a manufacturer that will suit your business needs, and more importantly, your budget.